Unraveling the Advantages and Disadvantages of Vanadium Oxide and Amorphous Silicon in Uncooled Infrared Detectors

WhatsApp/ Wechat: 0086-18291418396

Vanadium Oxide and Amorphous Silicon. As industries seek precision and reliability in thermal imaging, understanding the distinctive qualities of these materials becomes pivotal. This article delves into the intricacies of each, offering a comprehensive analysis to aid in informed decision-making.

Vanadium Oxide Uncooled Infrared Detectors

Advantages:

①High Sensitivity: Vanadium Oxide detectors exhibit high sensitivity to infrared radiation, making them adept at detecting subtle temperature variations.

②Broad Spectral Range: These detectors cover a broad spectral range, allowing for versatile applications across various industries, from medical diagnostics to industrial processes.

③Enhanced Image Quality: Vanadium Oxide detectors often yield higher image quality due to their superior temperature sensitivity, making them ideal for applications demanding precision and clarity.

Disadvantages:

①Limited Long-Wave Performance: Vanadium Oxide detectors may experience limitations in long-wave infrared detection, impacting their effectiveness in certain applications.

②Higher Manufacturing Costs: The production process for Vanadium Oxide detectors can be more complex, leading to higher manufacturing costs compared to alternative materials.

Amorphous Silicon Uncooled Infrared Detectors

Advantages:

①Cost-Effectiveness: Amorphous Silicon detectors are often more cost-effective to produce, making them an attractive option for applications where budget considerations are crucial.

②Versatility: These detectors offer a good balance between sensitivity and versatility, making them suitable for a range of applications, including consumer electronics and thermal cameras.

③Long-Wave Performance: Amorphous Silicon detectors tend to perform well in long-wave infrared, extending their applicability in scenarios where extended detection ranges are essential.

Disadvantages:

①Lower Sensitivity: Compared to Vanadium Oxide, Amorphous Silicon detectors may have lower sensitivity, impacting their ability to detect subtle temperature differences.

②Narrower Spectral Range: The spectral range of Amorphous Silicon detectors might be narrower than that of Vanadium Oxide, limiting their suitability for certain specialized applications.

Choosing the Right Material:

The choice between Vanadium Oxide and Amorphous Silicon hinges on the specific requirements of the intended application. While Vanadium Oxide excels in high-sensitivity, precision-demanding scenarios, Amorphous Silicon offers a cost-effective and versatile alternative for applications where a balance of sensitivity and budget considerations is paramount.

IREEDA's Commitment to Excellence:

IREEDA, at the forefront of technological innovation, understands the significance of material selection in uncooled infrared detectors. The company's commitment to excellence ensures that its products, whether incorporating Vanadium Oxide or Amorphous Silicon, meet the diverse needs of industries seeking cutting-edge thermal imaging solutions.

IREEDA's in-depth analysis of Vanadium Oxide and Amorphous Silicon in uncooled infrared detectors underscores the importance of tailored solutions in the evolving landscape of thermal imaging. As technology continues to advance, the choice between these materials becomes a strategic decision, with IREEDA leading the way in providing sophisticated solutions that redefine the possibilities of precision and reliability in thermal imaging applications.

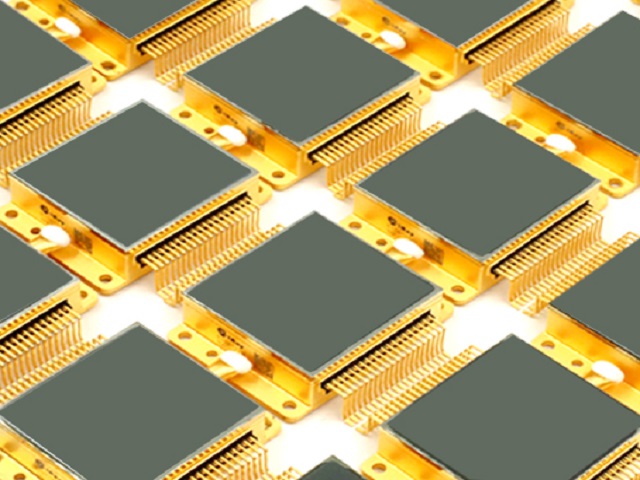

●17 µm pixel pitch

●1024 x 768 FPA

●8 - 14 µm spectral range

FEATURES:

—High quality images with sharp contrast (30 < NETD < 50 mK F/1, 300 K, 30Hz)

—Detects fast moving objects ( Frame rate: 2 outputs up to 60 Hz / 4 outputs up to 120 Hz)

—Array operability (> 99.5 %)

—Low power consumption (< 220 mW)

—Operability 24/7 (in all weather conditions)

WhatsApp/ Wechat: 0086-18291418396