Unveiling Resolution Secrets: Exploring the Differences between 640x512 and 340x288 Detectors in Thermal Imaging

WhatsApp/ Wechat: 0086-18291418396

Understanding Detector Resolution: The detector resolution refers to the number of pixels in the horizontal and vertical dimensions of the camera's sensor array. Higher resolution detectors, such as 640x512, have more pixels compared to lower resolution ones, for example, 340x288. Each pixel represents a temperature measurement point in the captured thermal image.

Image Clarity and Detail: One significant advantage of higher resolution detectors is their ability to capture finer details and provide sharper image clarity. A 640x512 detector, with 327,680 individual temperature measurement points, can produce more precise thermal images compared to a 340x288 detector with 98,304 pixels. The greater number of pixels allows for a higher level of detail, making it easier to identify smaller objects or temperature variations in complex scenes.

Extended Detection Range: Higher resolution detectors, by capturing more pixels, offer an extended detection range. They can detect smaller temperature differences, making them suitable for applications where detecting subtle variations is crucial. For instance, in thermal inspections for electrical components, a 640x512 detector can reveal minute temperature variations, aiding in identifying potential faults or anomalies.

Field of View Considerations: While higher resolution cameras may provide superior image detail, it's important to consider the trade-off in terms of field of view (FOV). In general, lower resolution detectors cover a larger FOV compared to higher resolutions. This means that a camera with a 340x288 detector can capture a wider area in a single frame, which can be advantageous in applications requiring broad scene monitoring or surveillance.

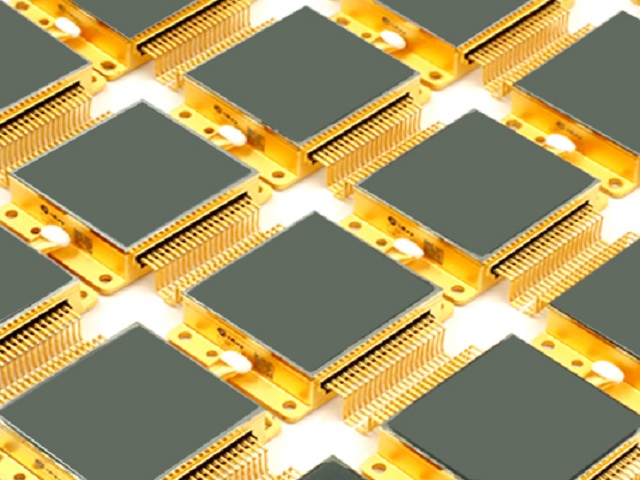

Cost and Affordability: The difference in detector resolution also affects the cost of thermal cameras. Higher resolution detectors typically come with a higher price tag due to the increased complexity and manufacturing processes required. Lower resolution cameras, on the other hand, provide a more cost-effective solution for applications where extensive image detail may not be critical.

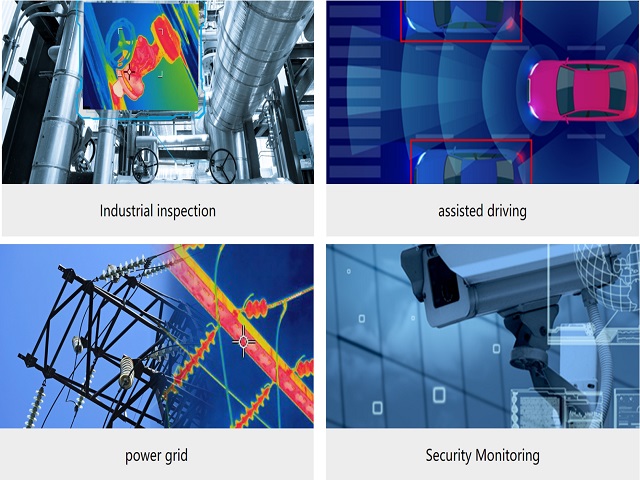

Application Scenarios: The choice between a 640x512 and a 340x288 detector depends heavily on the specific application requirements. Here are some scenarios where each resolution has its advantages:

640x512 Detector:

1. Scientific research and development, where precise temperature measurement and analysis are paramount.

2. Industrial inspections that demand the utmost accuracy and detailed identification of small temperature variations.

3. Professional thermographers and experts who require the highest image quality for accurate diagnostics.

340x288 Detector:

1. Building inspections, where a broader FOV is essential for capturing large areas or surveying for energy inefficiencies.

2. Security and surveillance, where wide-angle monitoring of outdoor spaces or perimeters is necessary.

3. General-purpose applications that prioritize cost-efficiency without compromising basic temperature analysis and detection capabilities.

Conclusion: The choice between a 640x512 and a 340x288 detector comes down to striking a balance between image quality, detection range, field of view, and cost considerations. While a higher resolution detector provides enhanced image detail and increased accuracy, it might not always be necessary for every application.

Please tell us your demands, let our Ireeda’s professional engineering manager evaluating the specific requirements of your thermal imaging needs will help determine the most suitable resolution, ensuring optimal performance and cost-effectiveness.

WhatsApp/ Wechat: 0086-18291418396